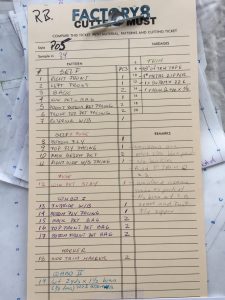

A properly annotated cutter’s must for a pair of men’s dress pants.

If you know us here at Factory8, you know how much we love a proper cutter’s must. But why? In a nutshell, a proper cutter’s must assures that the cutter will complete his or her job correctly. Correct cutting is just as essential as correct sewing in making sure that a garment is properly mass produced.

A proper cutter’s must often spells the difference between a pattern made by a sample hand and one made to go into production. Often sample hands will include a few directions on the outside envelope of their pattern, but really the cutter or seamstress must take out the pattern, place it on the table, and try and figure out what piece goes in which fabric…a bit like a puzzle. Or, if they are already familiar with the pattern because they made it themselves, they already know what goes where. However, this will not do for production, where many people down the whole supply chain must be able to interpret the pattern in exactly the same way. Good production begins with an excellent pattern and a cutter’s must is ESSENTIAL to this. A cutter’s must is like the map key to your pattern, as it provides an itemized list of all the pattern pieces that pertain to a particular style. It will tell you how many types of fabric there are, and which pattern pieces are cut in which fabrics. It will tell you how many pieces of each pattern to cut. It lists the pattern pieces by name and pattern # so there is no confusion regarding which pattern piece is being referenced. This is why all grading and marking specialists absolutely require it, otherwise they will not be able to make the marker!

As an additional precaution, you should always include a reference garment for the cutter, or if that’s not possible at the very least a sketch. While technically the cutter should be able to follow a proper cutter’s must, having an excellent visual on hand only helps to minimize any potential confusion and is especially recommended for more complex garments.