Denim Part 2: The Manufacturing Process

By Anya Ferring

Like any garment, creating the perfect pair of jeans requires going through the pattern development process, which as always is a process of finalizing fit and construction. Both of these areas are a bit more specialized when it comes to denim, however.

DEVELOPMENT

Fit: Garment specs, reference samples, and seam construction are taken into consideration when building out the pattern. Once the pattern is finished it is cut and sewn in the denim. Now, if you are applying a wash finish of any type to the jeans (more on this next week), the same wash must be applied at the development phase after the sample has been sewn. This is because it will shrink in various places post wash, and the patternmaker will take the post wash specs/fit and compare them with pre-wash specs/fit, and then add what was shrunk away into next pattern correction. In this way the wash/finish process can be controlled for at the development patternmaking stage. Some people prefer to do a shrink test on a swatch of denim prior to creating the pattern, and then build that rate of shrinkage into the jean, but the more complicated the wash the better it is to wash test on the garment itself and not just a small swatch. This is because the garment will shrink differently in different places accoriding to seam construction, especiallay if the wash or hand-finishing processes are applied to specific areas of the garment only. Building in the correct pattern shrinkage is the essence of creating the perfect fitting jeans!

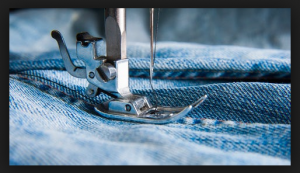

Construction: Traditionally jeans are constructed using a flat fell machine on the inseam (a felled seam is made by folding a raw edge of fabric underneath itself and then stitching the fold down), using a doubleneedle around the front fly, pockets, and beltloops, and applying bartacks and/or rivets at certain stress points.

After the pattern and fit have been approved, the product is ready to move onto the manufacturing phase, which involves scaling out the cut and sewing, and then applying the final finishing processes, which we will discuss next week.