Grading: What Every Designer Must Know

By Anya Ferring

What exactly is pattern grading? The purpose of grading is to proportionally increase or decrease the size of a pattern, while maintaining shape, fit, balance, and scale of all style details.

Grading is different from alteration in that grading is used to increase or decrease a size, based on an average difference between sizes, whereas alteration is used to make a particular size conform to an individual’s personal figure. In fact, grading was invented at the time clothing became mass-produced some 150 years ago as a way to scale out production and quickly and effectively reach a broader consumer market. Before this period, there wasn’t really a concept of “size,” and all clothing was made-to-measure to each individual.

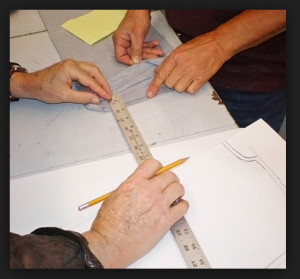

Once you have a base pattern established and fit approved, the grader will take a set of “grade rules” and apply them to the base pattern’s measurements to increase (if going up in size) or decrease (if going down in size) the measurements incrementally. Grading will not create shape, but will only increase or decrease size of original shape. This can be done manually or digitally using computerized pattern cutting software, though typically no one in the industry does this by hand anymore. Each specific clothing market and region have different grading rules, so it’s important to know where your market is, and who your demographic is.

Most designers and brands don’t need to be bothered with the technicalities of grading beyond a basic understanding—there are professionals and software programs to take care of that—but there are a few things that need to be considered when designing. For example, do you have zippers or some other trim placed in an area of the design that might be affected by grading? If you have a center front zip down hoodie, be aware that your garment would traditionally be graded in body length, and therefore you would need to plan on ordering multiple lengths of zippers to accommodate the different sizing. Skirts that are cut on the bias or otherwise require wide widths might work in your sample yardage at smaller sizes, but once they are graded out into larger sizes they may not fit your selected yardage. Or what about pocket placement? If you have special pocket design that involves a placement pattern, it might look odd when graded out into larger sizes. Keeping these concerns in mind at the development phase can help to alleviate problems from showing up in your bulk production orders down the line, headaches we’d all like to avoid.