What Are Matchlines, And Why Do They Matter?

Matchlines on production marker

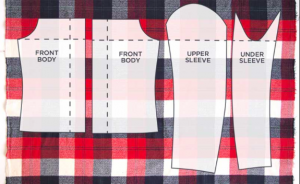

Laying out pattern matchlines for sample cut

Artists have long been aware that any disruption in the flow of a pattern draws the eye. While fashion designers can use this phenomenon in a pleasing way to produce visual interest, most often we avoid it by continuing the pattern of stripes, plaids, or large prints across visible seams in as unbroken a manner as possible, aiming for a balanced, harmonious effect. A “matchline” refers to the line drawn on a pattern where the plaid or stripe fabric must be matched in order that the textile pattern appears to flow unbroken across seam lines. (For the purposes of this article we will just be discussing stripes and plaids, though the same principles can apply for directional and large repeat prints). The cutting process is entirely different from cutting solids or non-repeat fabric prints, and so often adds another layer of complexity to the production garment costing process as well.

Producing effective textile matchlines on a production marker is more of a technical process than cutting a one-off. When cutting a sample it is somewhat easier to eyeball pattern placements on top of lines, and fabric consumption is generally not a concern. However, when scaling out to production and dealing with multiple sizes, fabric yields can quickly grow to unaffordable amounts if matchlines are not accounted for properly.

The amount of additional fabric you will need to achieve a good pattern match will depend on a number of factors, including the complexity of the garment design and the scale of the pattern. General rules of thumb are to focus on matching the most visible seams first. For example, when others look at you they spend the most time looking at your face, so make the center front pattern pieces match as your first priority, as these are the ones closest to your face.

As you are thinking about your front view, if your pattern has sleeves, particularly mid- to long-length sleeves, consider pattern matching the front of your sleeves to the front of the shirt or bodice. Your next priority is to match your center back, if you have a center back seam. After matching your center front and center back, consider pattern matching the waistline of a dress or jumpsuit to the bodice, or making an attractive pattern offset. Side seams are usually less important to match if you have a limited amount of material. For pants, match the outer side seam first and the inseam secondary.

Pattern making software will automatically align the patterns in a marker for matching a motif or plaid, according to your matchline priorities. As pieces are placed, they snap to the correct placement based on the matching lines taking into consideration seam allowance and other factors.

While garments with matchlines will always require higher yields than their solid color counterparts, by smartly prioritizing which seams will receive matchlines and utilizing marker-making software with your production specialists you can avoid high and costly fabric yields.

Plaid matchlines

Stripe matchlines